The most sustainable option?

Wearing what you already have.

THE second most sustainable?

Giving forgotten fabric a second life. That’s where our Special Projects come in.

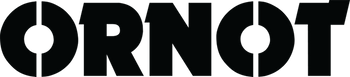

We work with deadstock fabric—textiles that were overproduced, abandoned, or just never made it to the cutting table. Instead of letting it sit in a warehouse (or worse, a landfill), we turn it into something new. The catch? We only get one shot. Each roll of fabric is a creative puzzle—jersey? Hoodie? Something totally unexpected? Once it’s used up, it’s gone. No restocks, no do-overs.

Introducing

Deadstock

Some of our most-loved pieces have come out of this process. And because everything’s made in California, we’re keeping things close to home. Less waste, more rad gear.

Check out our unique pieces before they vanish:

Introducing

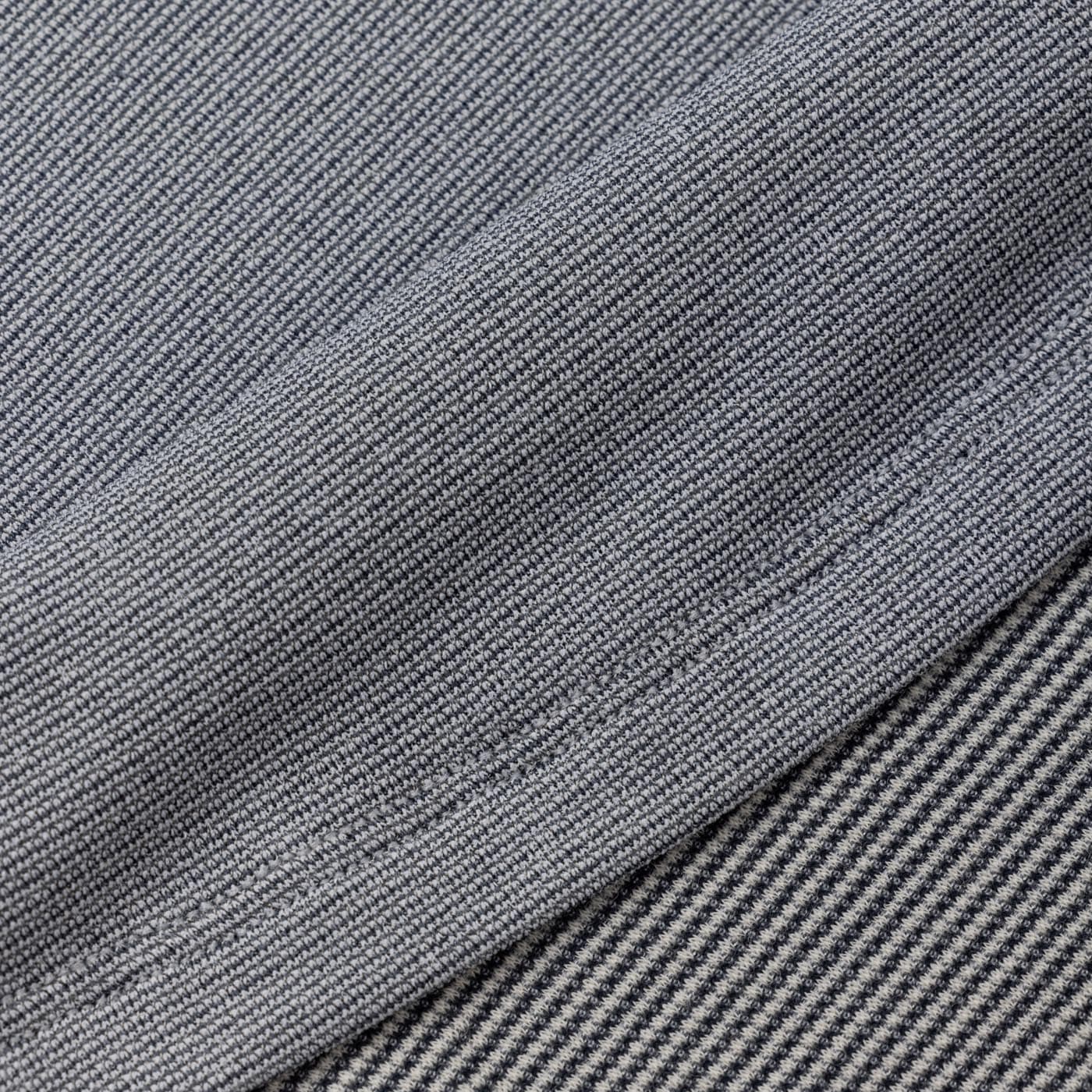

SPECIAL PROJECTS x POLARTEC

Great minds think alike—and by great minds, we mean anyone who sees the potential in leftover fabric. Polartec has been pioneering recycled textiles for years, which makes them a natural fit for our Special Projects. Whether it’s upcycling deadstock or reinventing performance fabrics, we’re both on a mission to make more out of what’s already here.

Introducing

POLARTEC

Polartec and the outdoors go together like bikes and snacks—so teaming up was a no-brainer.

With a shared commitment to sustainability, we're turning recycled and deadstock fabrics into high-performance gear, offsetting emissions, and keeping plastic out of landfills.

Polartec has a history of firsts—Soda-Bottle Green fleece, softshell revolutions, and fabrics that shed fewer microfibers. Now? Waterproofing made partly from plants. Science!

As our partnership grows, so does our lineup of smarter, more responsible gear. Ride in it, geek out over it, or both.

Our Fabrics:

special projects collection

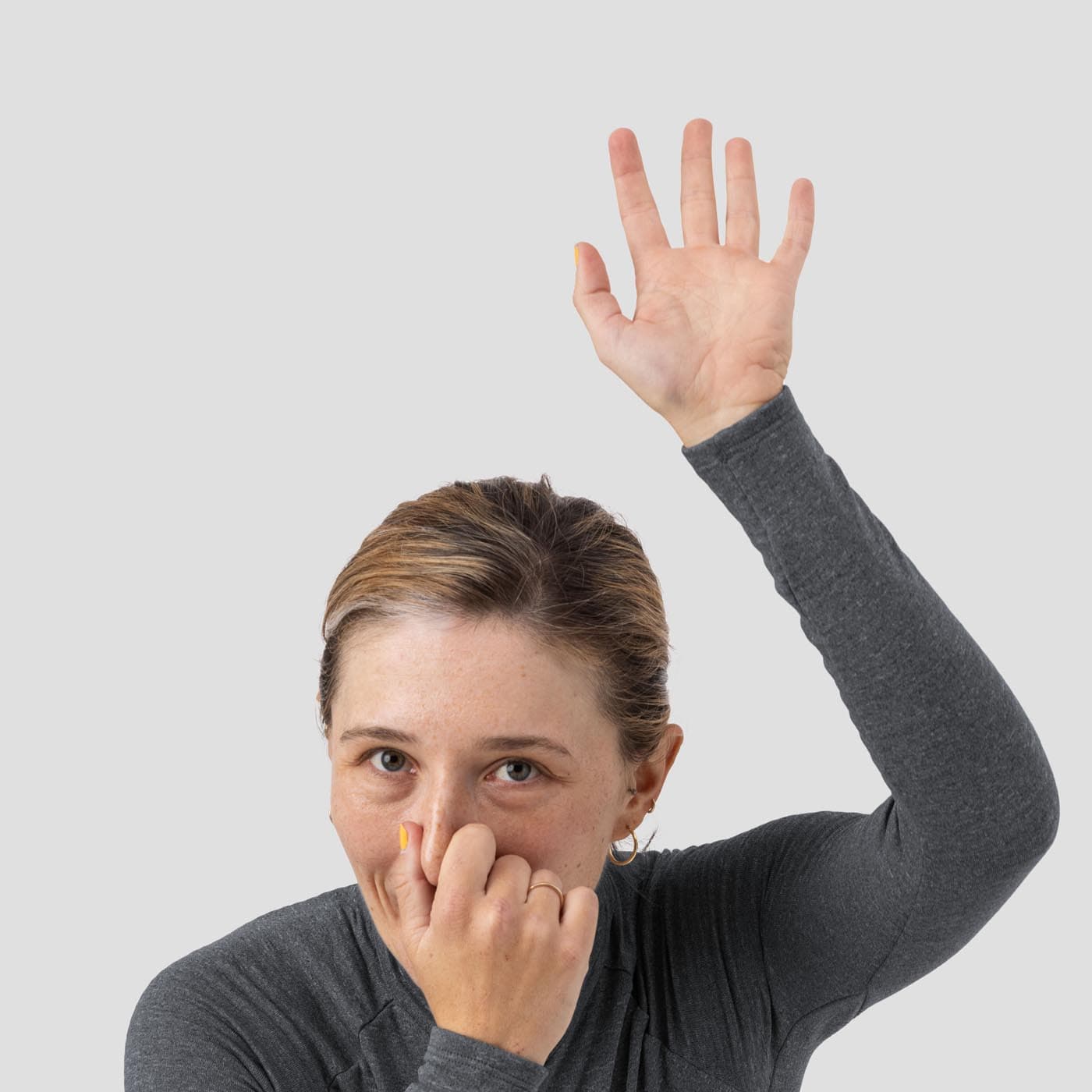

Wear it on your bike, ornot

An everyday essential built with three of our favorite things: a gridded fleecy interior, Merino Wool, and deadstock fabric.